In the global chemical supply chain, calcium carbide (CaC₂) stands out as a key raw material with unique physicochemical properties and critical safety considerations. However, mastering its storage requirements remains a challenge for many exporters and importers, especially given its reactive nature with moisture which releases acetylene gas—a highly flammable and potentially hazardous substance.

This guide delves into the intrinsic characteristics of calcium carbide, dissecting its reactivity and the precise environmental conditions necessary for safe and quality-preserving storage. Drawing from international standards and real-world incidents, it highlights operational best practices instrumental in safeguarding export quality and supply chain integrity.

Calcium carbide is a grayish-black solid, primarily used for acetylene production in welding, chemical synthesis, and metallurgical processes. One defining chemical property is its vigorous reaction with water:

| Reaction Equation | Description |

|---|---|

| CaC₂ + 2H₂O → C₂H₂ (acetylene) + Ca(OH)₂ (calcium hydroxide) | Exothermic & generates flammable acetylene gas when exposed to moisture |

This reaction is not just a minor inconvenience; improper storage leading to moisture ingress can cause uncontrolled acetylene release, leading to fire or explosion hazards. Moreover, even slight exposure to humidity can degrade the product quality, resulting in lower purity and inconsistent performance when supplied to customers abroad.

From a scientific and practical standpoint, storage of calcium carbide demands strict control over environmental factors:

Alongside these measures, proper labeling and safety signage are non-negotiable to alert handling personnel. Regular inspection and monitoring of storage conditions using hygrometers and acetylene gas detectors can identify risks early.

Evidence from reported accidents underscores the gravity of inadequate storage. For example, a mid-sized chemical exporter in Southeast Asia faced a shipment recall after excess moisture in warehouse conditions led to premature acetylene release. The resulting compromise in product purity caused customer rejection and a financial loss exceeding $150,000.

Another case involved a fire outbreak initiated by improper segregation of calcium carbide with strong oxidizers. This incident resulted in significant property damage and brought production to a halt for weeks, illustrating that risk management extends well beyond just the chemical itself.

Based on extensive industry experience and global best practices, exporters should integrate the following steps into their operations:

| Step | Action | Purpose |

|---|---|---|

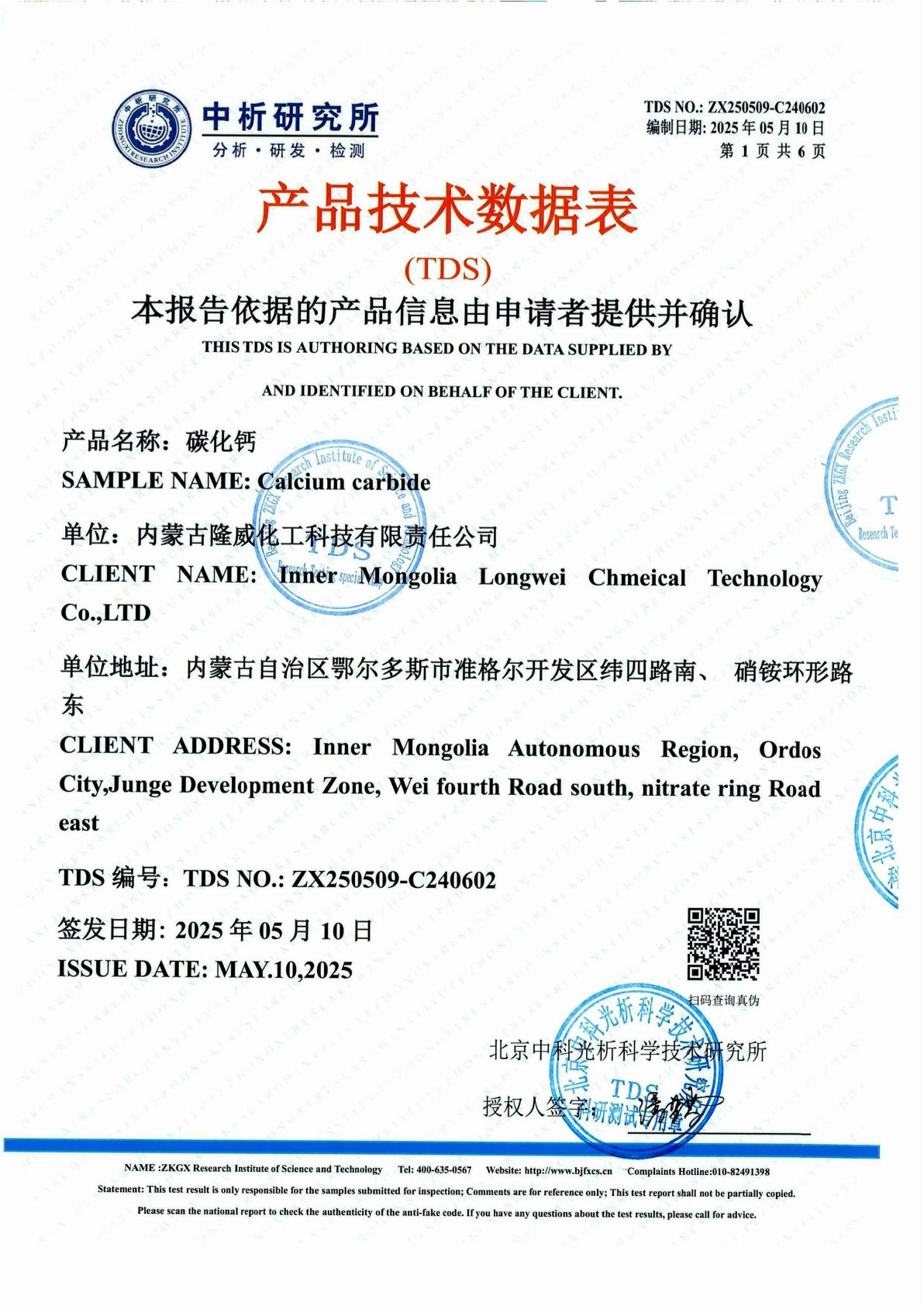

| 1 | Pre-shipment Quality Testing | Verify moisture content & acetylene potential to ensure product consistency |

| 2 | Sealed Packaging with Desiccant Packs | Prevents moisture ingress during transit |

| 3 | Climate-Controlled Warehousing | Maintains stable temp & humidity, limits chemical degradation |

| 4 | Regular Safety Audits & Staff Training | Ensure compliance with safety protocols and reduce operational risks |

The combination of these controls secures not only the physical product quality but also builds trust with international buyers who increasingly demand transparent and risk-managed supply chains.

Leveraging decades of expertise in chemical exports, our company specializes in calcium carbide supply with state-of-the-art storage and logistics infrastructure. This ensures superior product stability, minimizes incident risks, and offers clients the competitive advantage of consistent quality delivery worldwide.

If you are looking to enhance your supply chain reliability and protect your export reputation, adopting scientific storage solutions isn't optional—it's indispensable.