Calcium carbide remains an essential chemical raw material universally recognized for its invaluable contribution to acetylene gas production and oxygen welding sectors. The compound’s unique chemical nature enables reliable and efficient acetylene release upon contact with water, positioning it as a cornerstone in industrial applications worldwide. This article dives into calcium carbide’s chemical properties, stringent quality control measures ensuring high purity, and a monthly production capacity of 2,000 tons supported by robust manufacturing infrastructures. Further, it explores its broad market applications in India, the Middle East, Africa, and beyond, emphasizing the value of safety and trust in supply chain management.

Chemically represented as CaC2, calcium carbide exhibits a crystalline solid structure known for its pronounced reactivity with water, yielding acetylene gas (C2H2) and calcium hydroxide. Industrially, this reaction is harnessed to generate acetylene, a crucial fuel and chemical intermediate used extensively in oxy-acetylene welding, metal cutting, and organic synthesis.

| Property | Typical Value | Importance |

|---|---|---|

| Purity (%) | ≥ 75 | Ensures efficient acetylene release & minimal impurities |

| Moisture Content (%) | ≤ 0.5 | Prevents premature acetylene escape & enhances shelf life |

| Free Lime (%) | ≤ 20 | Affects combustion quality and welding flame stability |

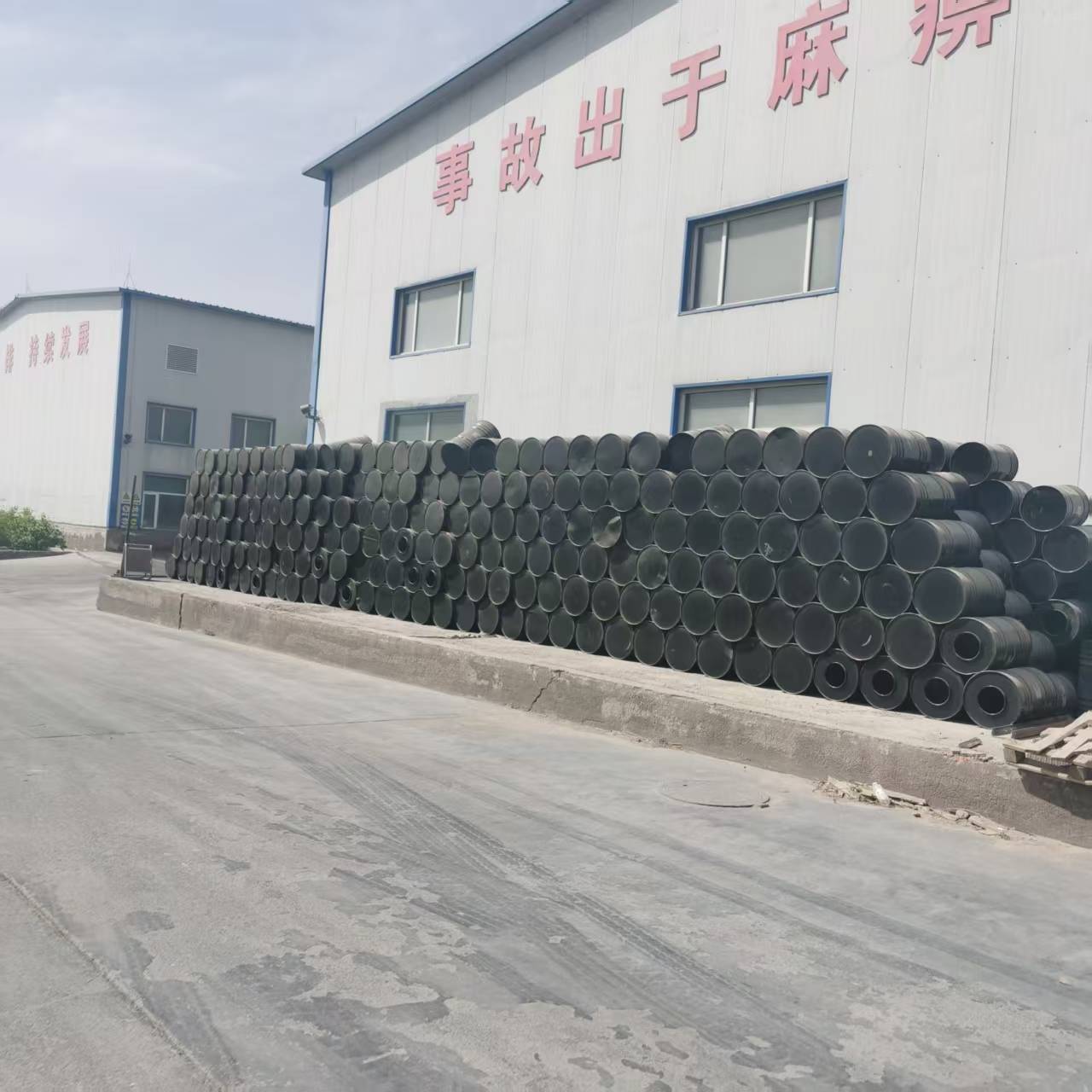

With a consistent monthly output of 2,000 tons, the manufacturing process leverages legacy expertise and modern quality management systems to secure product uniformity and compliance with international standards. Each production batch undergoes rigorous analysis for chemical composition and physical attributes, adhering to ISO 9001 protocols. This guarantees that clients receive calcium carbide that not only meets but often exceeds purity benchmarks, pivotal for applications demanding safety and reliability.

Our calcium carbide solutions are deeply integrated into diverse geographic markets, including India, the Middle East, and African regions, each with unique operating conditions and regulatory landscapes. Tailored supply strategies encompass specialized packaging to ensure safe transit over long distances, minimizing moisture ingress and contamination risks. Feedback from welding workshops and industrial users attests to the superior performance and consistent supply chain reliability.

The hazardous nature of calcium carbide demands uncompromising safety protocols from synthesis to shipment. Strict handling and storage guidelines prevent accidental water contact, eliminating risks of fire or explosions. Packaging adopts moisture-resistant materials certified for international transport regulations, and logistic partners undergo continuous safety training. Transparent communication channels further empower customers with handling best practices and emergency procedures.

Several industries testify to the impact of superior calcium carbide supply on productivity and safety. For instance, an Indian metal fabrication plant reported a 15% increase in welding efficiency after switching to our high-purity calcium carbide. In the Middle Eastern construction sector, our adherence to packaging standards reduced shipment damage incidents by over 30%. These practical outcomes underscore the synergy between product excellence and operational trustworthiness.

We invite industry professionals and technical experts to share their insights or challenges regarding calcium carbide applications. How does purity affect your acetylene generation efficiency? What safety protocols have you found most effective? Your experience can drive innovation and community learning.