In the chemical industry, calcium carbide is a widely used raw material. However, its use comes with significant risks, primarily the potential for acetylene gas explosions and phosphine poisoning. Inner Mongolia Longwei Chemical Technology Co., Ltd. has been at the forefront of addressing these risks through meticulous component analysis and strict quality control.

Calcium carbide (CaC₂) is a chemical compound that reacts vigorously with water to produce acetylene gas (C₂H₂). The reaction is as follows: CaC₂ + 2H₂O → C₂H₂ + Ca(OH)₂. Acetylene is highly flammable and explosive, with an explosion limit in air ranging from 2.5% to 82%. Even a small spark can trigger a violent explosion.

Another significant risk is associated with the presence of calcium phosphide (Ca₃P₂) in calcium carbide. When calcium phosphide reacts with water, it produces phosphine (PH₃), a highly toxic gas. Exposure to phosphine can cause symptoms such as headache, dizziness, nausea, and in severe cases, can be fatal. According to statistics, in the past decade, there have been several industrial accidents related to calcium carbide use, resulting in multiple casualties and significant property losses.

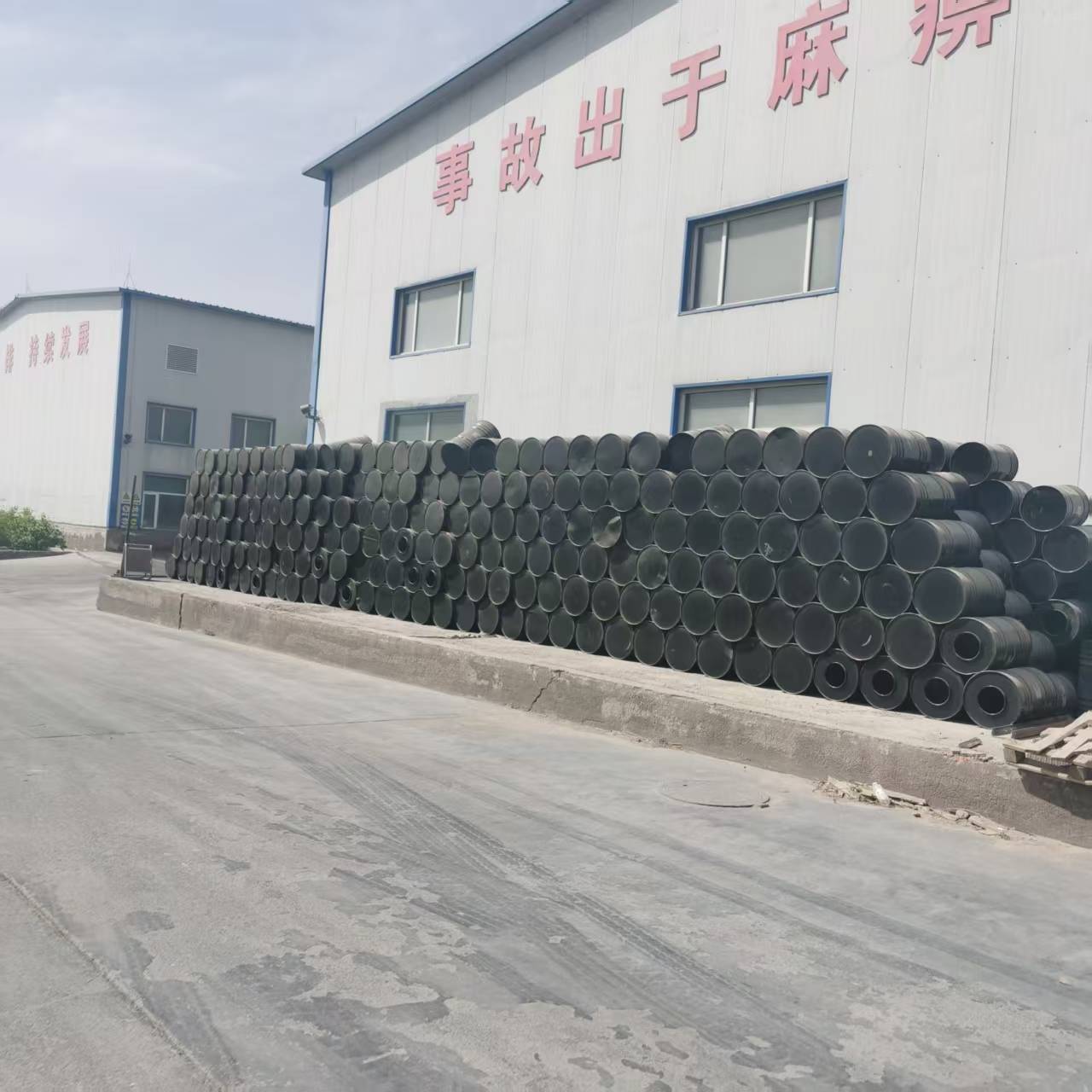

Inner Mongolia Longwei Chemical Technology Co., Ltd. is committed to providing high - quality calcium carbide products. The company has established a strict quality control system. Their calcium carbide products have a high purity level, typically above 90%, which significantly reduces the content of impurities such as calcium phosphide.

The company uses advanced component analysis techniques, such as X - ray fluorescence spectrometry (XRF), to accurately measure the content of various elements in calcium carbide. This allows them to identify and control potential risk factors. For example, by precisely measuring the content of calcium phosphide, they can take appropriate measures to ensure the safety of the product.

To prevent acetylene explosions, Inner Mongolia Longwei Chemical recommends strict adherence to operating procedures. For example, the storage and handling of calcium carbide should be kept dry, and the reaction equipment should be well - ventilated. In addition, all electrical equipment in the working area should be explosion - proof.

To avoid phosphine poisoning, the company emphasizes the importance of personal protective equipment. Workers should wear gas masks and protective clothing when handling calcium carbide. Regular air quality monitoring should also be carried out in the workplace to ensure that the phosphine concentration is within the safe range.

In a chemical plant in [city name], due to improper storage of calcium carbide, it came into contact with water, resulting in a large - scale acetylene explosion. The explosion caused serious damage to the plant and led to several casualties. In another case, workers were exposed to phosphine gas due to the lack of proper ventilation and personal protective equipment, resulting in severe poisoning.

These cases highlight the importance of proper calcium carbide use and risk management. Inner Mongolia Longwei Chemical's quality control practices can effectively prevent such accidents from happening.

We encourage you to share your thoughts and suggestions on calcium carbide safety. How do you think we can further improve the safety of calcium carbide use? Your feedback is crucial for us to continuously update and improve our content. By staying informed and implementing the latest safety measures, we can ensure a safer and more efficient production environment in the chemical industry.

If you are interested in learning more about Inner Mongolia Longwei Chemical's high - quality calcium carbide products and advanced risk management solutions, please click here.