Calcium carbide, a vital industrial chemical, has a wide range of applications in various industries. This article delves into how [Company Name] ensures the high purity and stability of its calcium carbide products through strict quality control measures, and explores its key applications in the industrial field.

Calcium carbide, with the chemical formula CaC₂, is a grayish - black solid at room temperature. It reacts vigorously with water to produce acetylene gas, which is widely used in the chemical industry, metallurgy, and welding. In the chemical industry, acetylene is a key raw material for the synthesis of various organic compounds, such as vinyl chloride, acrylonitrile, and 1,4 - butanediol. In metallurgy, calcium carbide is used as a desulfurizer and deoxidizer.

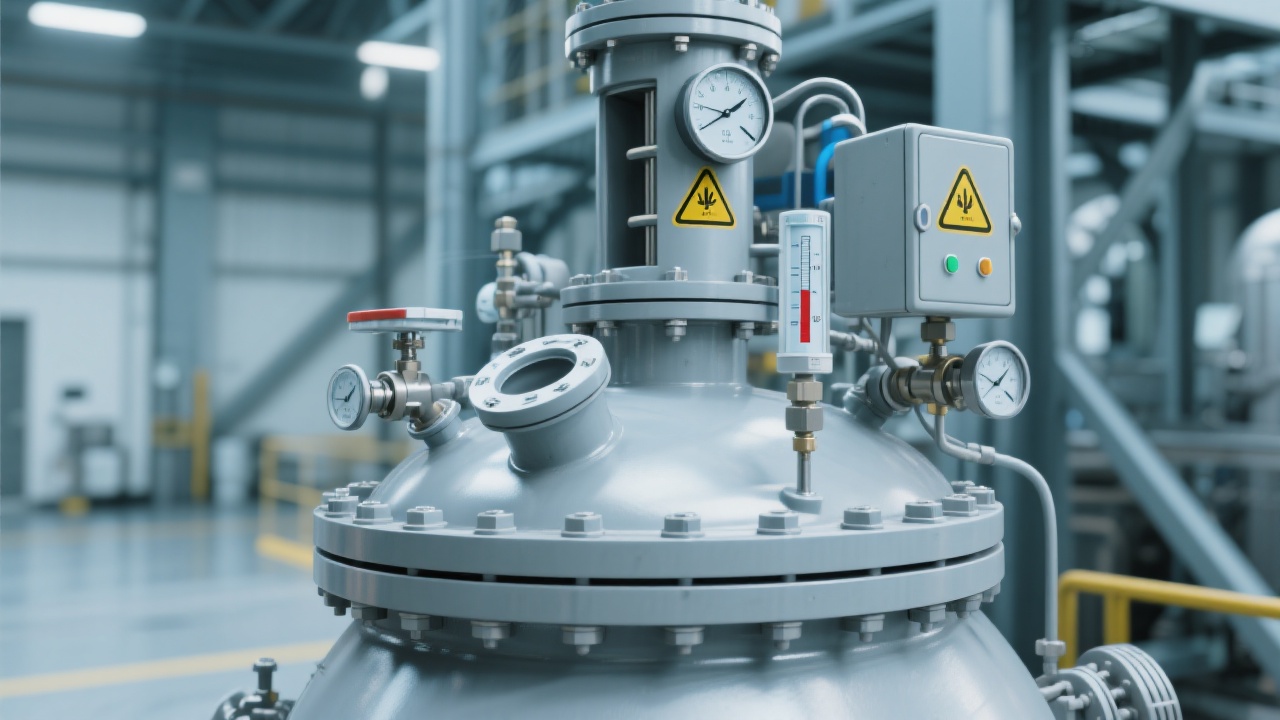

[Company Name] has established a strict quality control system throughout the production process of calcium carbide. The raw materials, mainly limestone and coke, are carefully selected. The limestone must have a calcium carbonate content of over 95%, and the coke should have a fixed carbon content of more than 85%. During the production process, advanced electric arc furnace technology is used, with strict control of temperature, current, and reaction time.

The company has set up a series of strict quality standards. For example, the purity of calcium carbide products must reach over 90%, and the content of impurities such as sulfur and phosphorus should be controlled below 0.05% and 0.03% respectively.

To ensure the high purity and stability of calcium carbide, [Company Name] has implemented a series of specific measures. Firstly, multiple purification steps are carried out during the production process to remove impurities. Secondly, real - time monitoring is conducted during the reaction process to ensure the stability of the reaction conditions.

In the quality inspection link, each batch of products undergoes a comprehensive inspection. Physical and chemical analysis methods, such as titration, spectroscopy, and thermal analysis, are used to detect the purity, particle size, and other parameters of the products. Only products that pass all the inspection items can enter the market.

In the chemical industry, high - purity calcium carbide is used to produce high - quality acetylene, which is then used to synthesize high - performance plastics, synthetic rubber, and fibers. For example, in the production of polyvinyl chloride (PVC), the use of high - purity calcium carbide can improve the quality and performance of PVC products.

In the metallurgical industry, calcium carbide is used as a desulfurizer and deoxidizer in the steel - making process. It can effectively reduce the sulfur and oxygen content in steel, improving the quality and mechanical properties of steel products.

[Company Name] has a strict packaging and transportation system. Calcium carbide products are packed in special steel drums or plastic - lined bags to prevent moisture and air from entering. During transportation, strict safety regulations are followed. The products are transported in sealed containers, and appropriate safety measures are taken to prevent accidents.

The company's annual production capacity of calcium carbide reaches 500,000 tons, and it has a complete logistics system that can ensure the timely and safe delivery of products to customers around the world.

[Company Name]'s calcium carbide products are sold in both domestic and international markets, covering Asia, Europe, and America. The company's products are well - recognized in the market due to their high purity, stability, and strict quality control. Compared with competitors, [Company Name] has a cost - effective advantage in terms of production technology and quality control, which gives it a strong competitiveness in the international market.

[Company Name] adheres to the principle of safety and integrity in production management. Through real - life cases and storytelling methods, the company shows its commitment to safety and quality. For example, in a large - scale project, the use of [Company Name]'s calcium carbide products ensured the smooth progress of the project and received high praise from customers.

We invite you to participate in the discussion. How important is quality control in your procurement decision - making process? Share your thoughts and experiences with us. If you want to learn more about our high - quality calcium carbide products, please click here.