Calcium carbide is a fundamental chemical raw material that plays a crucial role in the basic chemical industry. Its wide - ranging applications span across various sectors, making it an indispensable component in chemical production.

Calcium carbide has distinct physical and chemical properties. Physically, it has a certain appearance characteristic. Chemically, its most notable feature is its reaction with water to produce acetylene gas. This reaction is not only a key process in many chemical applications but also poses significant safety risks. For example, acetylene is a flammable and explosive gas. According to industry statistics, in chemical plants where calcium carbide is used, about 30% of safety incidents are related to the improper handling of the reaction between calcium carbide and water.

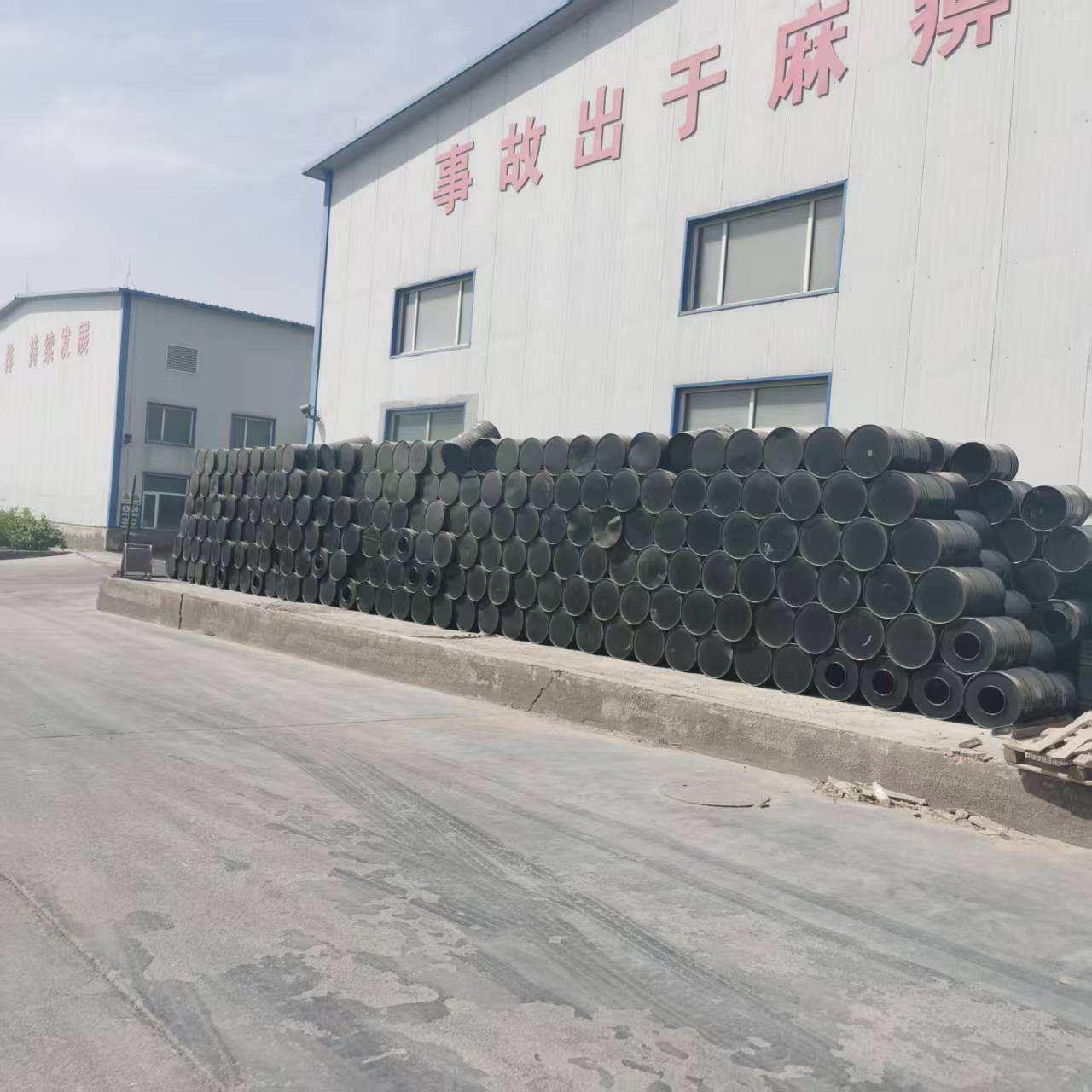

Proper storage of calcium carbide is essential to ensure safety and product quality. The storage environment should be cool, dry, and well - ventilated. The temperature should be controlled below 30°C, and the relative humidity should be kept below 70%. Good ventilation facilities are necessary to prevent the accumulation of acetylene gas. In addition, calcium carbide should be stored in sealed packaging to prevent moisture from entering. It is also crucial to isolate it from fire sources. Statistics show that more than 40% of calcium carbide storage accidents are caused by improper temperature and humidity control or proximity to fire sources.

Moreover, calcium carbide should not be stored together with acids and alcohols. These substances can react with calcium carbide, increasing the risk of explosion and fire. A table below summarizes the key storage environment requirements:

| Storage Requirement | Details |

|---|---|

| Temperature | Below 30°C |

| Relative Humidity | Below 70% |

| Ventilation | Good ventilation facilities |

| Packaging | Sealed |

| Fire Source Isolation | Keep away from fire sources |

In case of a calcium carbide leakage, a well - defined emergency handling process should be followed. First, evacuate all non - essential personnel from the area to a safe place. Then, cut off all potential fire sources and avoid any spark - generating operations. Next, use appropriate tools to collect the leaked calcium carbide carefully. If the leakage is large, professional disposal teams should be called immediately. A real - world case shows that in a chemical plant, due to improper handling of a small calcium carbide leakage, it eventually led to a large - scale explosion, causing significant economic losses and casualties.

To ensure the safe use and storage of calcium carbide, chemical enterprises should establish a comprehensive safety management system. Regular risk assessments should be carried out, and emergency response plans should be updated regularly. By analyzing typical safety accident cases, enterprises can learn from past mistakes and improve their safety management level. For example, through the analysis of several major calcium carbide storage accidents, it is found that lack of proper safety training and supervision is a common problem.

In conclusion, the safe management of calcium carbide is of utmost importance in the chemical industry. By following the proper storage requirements and emergency handling procedures, chemical enterprises can significantly reduce the risk of safety accidents. Our company offers professional products and safety service solutions for calcium carbide management. If you want to ensure the safety and efficiency of your chemical production, click here to learn more.