Case Analysis and Preventive Measures of Safety Accidents Caused by Improper Storage of Calcium Carbide

2025-08-28

Industry Experience

This paper conducts an in - depth analysis of typical safety accident cases caused by improper storage of calcium carbide. Combining practical experience in the chemical industry, it systematically sorts out the requirements for its storage environment, isolation of incompatible substances, and key points for emergency handling of leaks. It provides a practical safety management guide for relevant enterprises and practitioners, aiming to enhance the awareness of warehouse safety and the ability to prevent and control risks.

Calcium carbide plays a pivotal core role in the chemical industry chain. As a key raw material, it is widely used in the production of acetylene, polyvinyl chloride (PVC), and other important chemical products. However, its high reactivity poses significant challenges to storage. In this article, we will explore the storage safety of calcium carbide in depth.

Physical Properties and Key Characteristics

Calcium carbide exists in the form of white crystals or gray - black lumps. One of its most critical properties is its violent reaction with water. When calcium carbide comes into contact with water, it generates acetylene gas and releases a large amount of heat. This reaction is highly exothermic and can lead to rapid increases in temperature and pressure. Therefore, strict control of humidity and contact sources is essential to prevent potential hazards.

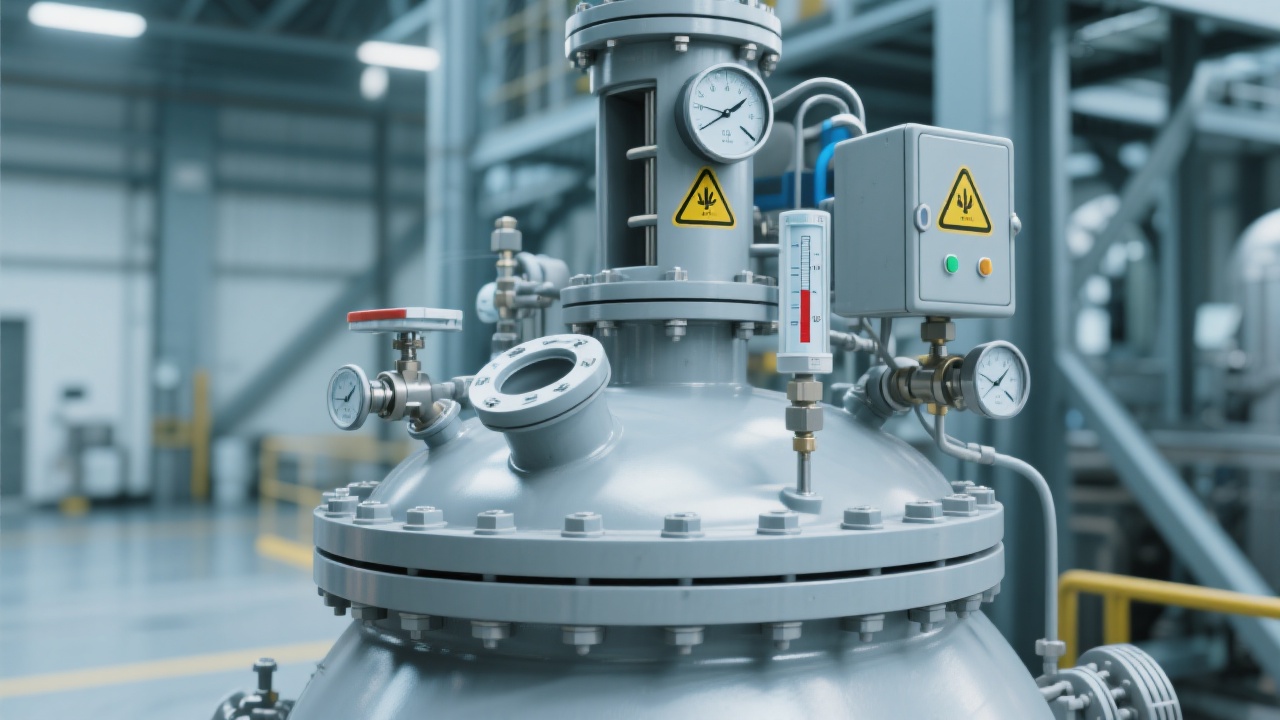

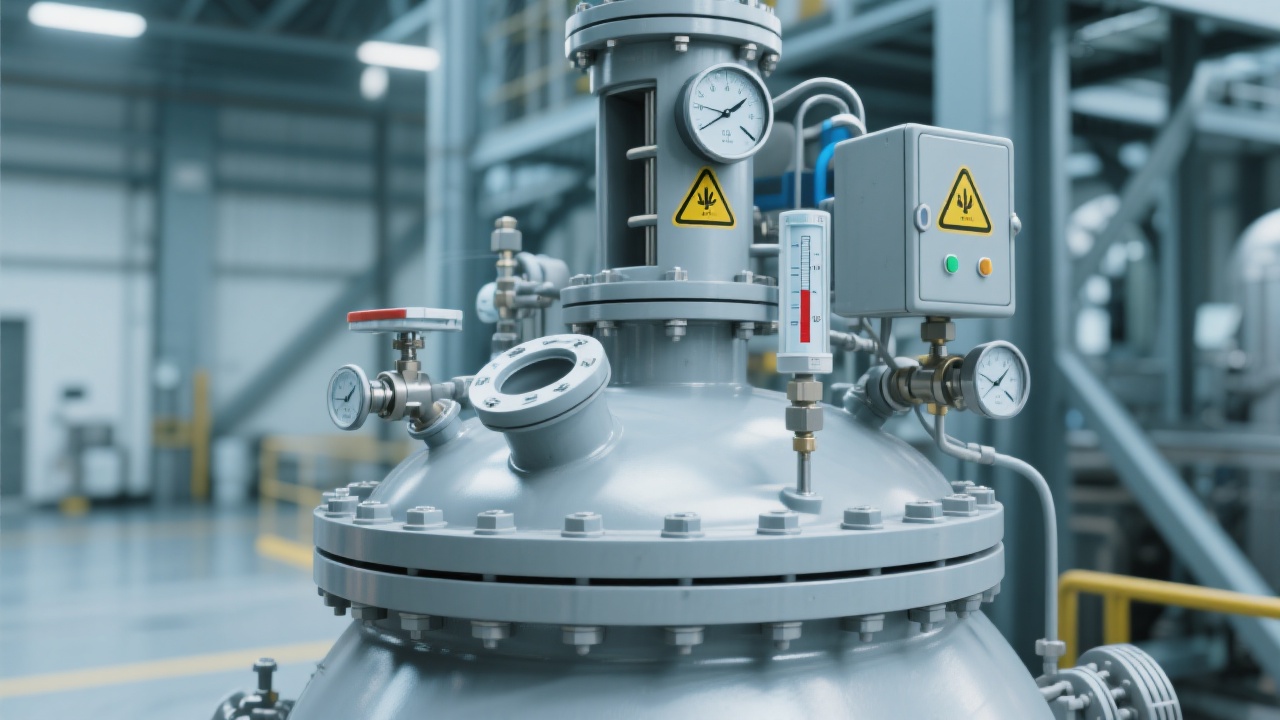

Storage Conditions

- Storage Environment: Calcium carbide should be stored in a cool, dry, and well - ventilated warehouse. The relative humidity in the warehouse should be ≤75%. This helps to maintain a low - humidity environment and reduces the risk of reaction with water vapor in the air.

- Packaging: It must be stored in sealed packaging to prevent moisture from entering. High - quality sealed containers can effectively isolate calcium carbide from the external environment.

- Distance from Ignition Sources: The storage area should be kept away from fire sources and heat sources. Even a small spark can ignite the acetylene gas generated by calcium carbide, leading to an explosion.

- Separation from Incompatible Substances: Calcium carbide should not be stored together with acids and alcohols. These substances can react with calcium carbide, causing dangerous chemical reactions.

Real - World Accident Cases

There have been several real - world accident cases related to improper storage of calcium carbide. For example, in a factory, due to the damp storage environment, calcium carbide reacted with water to generate acetylene, which eventually led to an explosion. The explosion caused direct losses of approximately $500,000 and seriously affected the normal operation of the factory. In another case, a warehouse stored calcium carbide together with acids. The reaction between them produced toxic gases, resulting in several workers being poisoned.

Analysis of Root Causes and Consequences

The root causes of these accidents mainly include negligence in storage management, lack of understanding of the properties of calcium carbide, and failure to follow storage regulations. The consequences are often very serious, including property damage, personal injury, and environmental pollution. These accidents not only cause economic losses to enterprises but also have a negative impact on the social image of the industry.

Preventive Measures

- Regular Inspections: Regular inspections of the storage area should be carried out to check for signs of moisture, damage to packaging, and the presence of incompatible substances. This can help to detect potential problems in a timely manner.

- Emergency Response Plans: Enterprises should develop comprehensive emergency response plans for calcium carbide storage. These plans should include procedures for dealing with leaks, fires, and explosions.

- Leak Containment Materials: Appropriate leak containment materials should be prepared in the storage area. These materials can quickly absorb and contain leaked calcium carbide to prevent further reactions.

- Employee Training: Employees should receive regular training on the properties of calcium carbide, storage regulations, and emergency response procedures. This can strengthen the safety culture within the enterprise.

Mastering these details can make your storage safer, more compliant, and more efficient. By implementing these preventive measures, enterprises can effectively reduce the risk of calcium carbide storage accidents and improve the overall safety level of the chemical industry. If you want to learn more about calcium carbide storage safety and other chemical product management knowledge, click here.